EXPERTS IN ROTOMOULDED TANKS

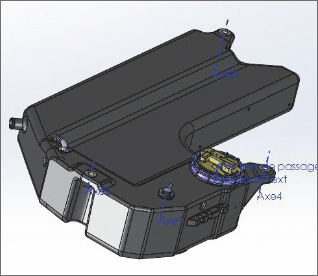

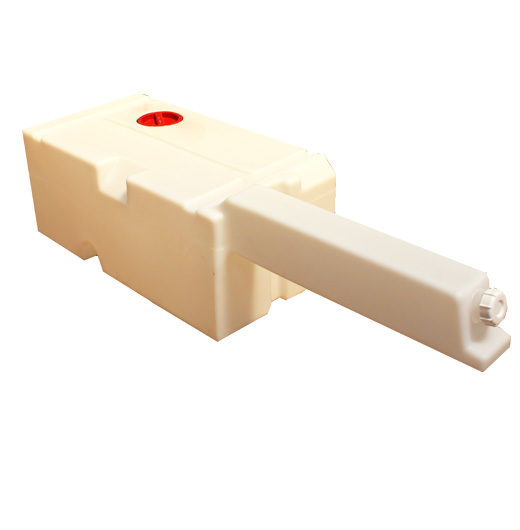

The GROUPE MAILLARD INDUSTRIE designs and manufactures specific tanks and/or visible tanks in rotomoulded plastic for any fluid.

These tanks are particular suited to the special vehicles market: HGVs, utility vehicles, trains, worksite machinery, 2-wheeled vehicles, camper vans, ambulances, armoured personnel carrier…

Experience in the rotomoulding techniques makes it possible to create lightweight tanks with a design adapted to the constraints of each vehicle.

Our skills at a

glance

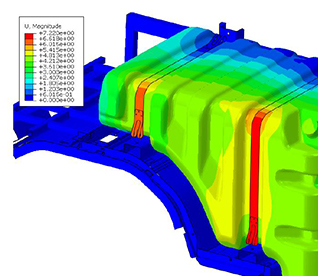

Bespoke design and simulation

Serial production

Management of regulatory requirements

Certification

Certification Assembly of complete functions

Quality control

Synchronous

FIFO Delivery

ISO 9001 and 14001

Depending on the use and type of fluid in question, tanks can be made in POLYETHYLENE (HDPE, LDPE, MDPE, PER…), POLYPROPYLENE (PP), POLYAMIDE (PA6, PA6-6, PA11, PA12)…

List of main fluids:

WATER, DIESEL, PETROL, LPG, UREA, COOLANT, HYDRAULIC OIL, WINDSCREEN WASHER, SPECIAL FLUIDS, BRAKE FLUID, WASTE WATER, CHEMICAL AGENTS, HELIUM, HYDROGEN, LIQUID FERTILIZER

Industrialisation – manufacture

The tools department manages the manufacture, validation and maintenance of the moulds independently to guarantees the flexibility and responsiveness of our production units.

Our production lines are able to manufacture complex tanks with inserts, accessories and screen printing from 0.5 to more than 30,000 litres.

Extensive experience in automated plastic welding means that we can create technical and aesthetic assemblies whilst guaranteeing the sealing of the tank, whatever its geometry.

Strict leakage tests are carried out on the production line and adapted to the constraints of each project.

Certification / Standard

GMI’s experience enables us to support customers in the partial or complete management of tank certification in France and internationally: TUV / UTAC / AIDIMA.

The application of PPAP procedures guarantees the reliability of the design, manufacturing and means implemented to meet customer requirements

Assembly and delivery

Delivery of complete functions ready to be assembled on a vehicle. (Plugging, filter, piping, pump, drain valve, gauge….). Our ERP operating system and our logistics unit allow us to manage the supply of parts and accessories supplied by our customers or sourced by our procurement department.

Tanks stocks can be managed internally using Fifo and/or JIT methods.

Impermeability

because the sides of the tanks are made without welding or gluing

Resistance

because they are manufactured without the use of tension in comparison with other plastics processing technologies

Lightweight

because the density is less than a metal tank

Anti-corrosion

because the material is inert and is not subject to oxidation

Recyclable

because the material is 100% recyclable